Views: 0 Author: Rachel Wynn Publish Time: 2025-05-26 Origin: Site

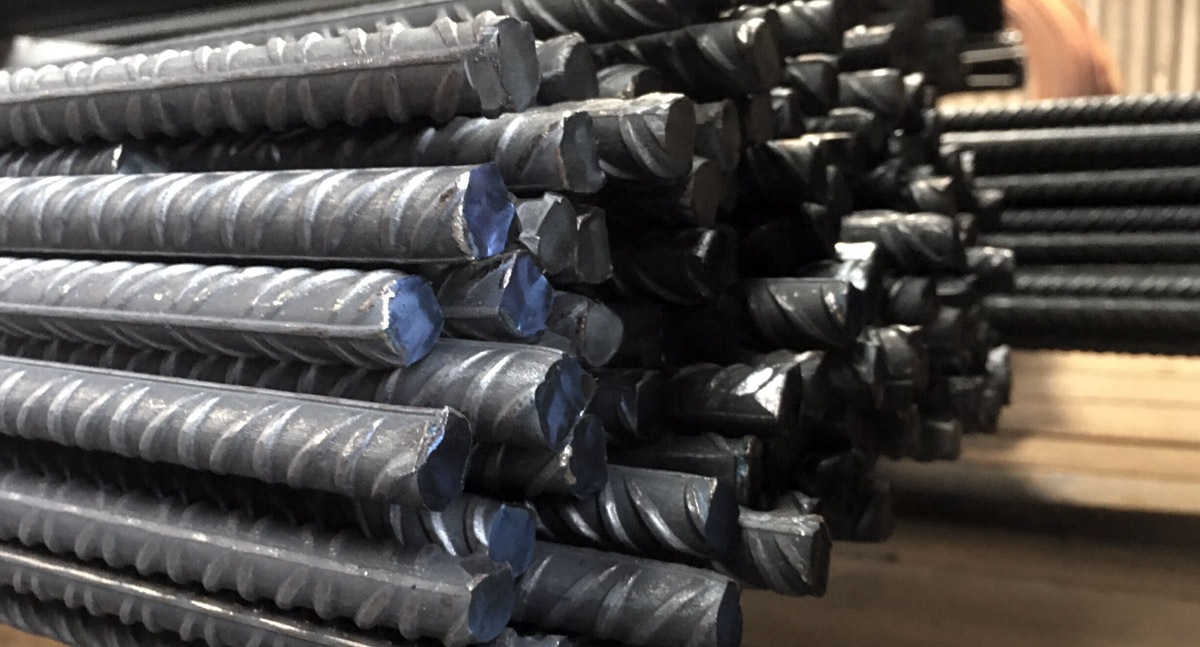

Reinforced steel, also called rebar (short for reinforcing bar), is a fundamental material in modern construction. It significantly enhances the structural performance of concrete, particularly in tensile strength, making buildings, bridges, highways, and tunnels more durable and resilient. In this comprehensive guide, we explore the properties, types, applications, and innovations in reinforced steel that are shaping global infrastructure.

Reinforced steel is steel embedded within concrete to form a composite material that handles both compressive and tensile forces. While concrete excels under compression, it lacks the ability to withstand tension. Reinforced steel compensates for this, providing a balanced structural system.

| Type | Description | Ideal Use | Corrosion Resistance |

|---|---|---|---|

| Carbon Steel Rebar | Most widely used type, high tensile strength | General construction | Low |

| Epoxy-Coated Rebar | Coated to resist corrosion in harsh environments | Coastal or industrial zones | Medium |

| Stainless Steel Rebar | Extremely durable and corrosion-resistant | Critical infrastructure | High |

| GFRP Rebar | Non-metallic fiberglass alternative | Marine and chemical facilities | Very High |

Yield Strength: Typically ranges from 250 MPa to 600 MPa depending on grade

Ductility: Allows deformation without fracture under stress

Modulus of Elasticity: ~200 GPa, ideal for handling dynamic loads

Thermal Compatibility: Expands similarly to concrete, minimizing cracks

Reinforced steel is foundational to both vertical and horizontal infrastructure:

Used in slabs, columns, beams, and foundations, reinforced steel ensures stability under vertical and lateral loads.

Highways, bridges, and tunnels require reinforced steel to handle vibration, weight, and environmental stress.

Structures exposed to saltwater or underground pressure benefit from corrosion-resistant rebar types.

Used in factory-made concrete elements for quick assembly on-site, increasing construction speed and efficiency.

Enhances tensile strength and overall structural performance

Increases lifespan and reduces maintenance needs

Complies with global building codes and seismic standards

Supports innovative architecture with larger spans and thinner sections

Prone to corrosion if not properly coated or maintained

Material costs may vary based on global steel prices

Requires careful detailing and placement to avoid structural failures

Below is a simplified table showcasing global consumption trends (estimates):

| Region | 2022 Rebar Demand (Million Tons) | Growth Forecast (2025) |

|---|---|---|

| Asia-Pacific | 430 | +5.2% |

| Europe | 125 | +2.8% |

| North America | 90 | +3.1% |

| Middle East & Africa | 60 | +4.0% |

New technologies allow embedding sensors in rebar to monitor structural health, detect corrosion, and alert engineers in real time.

Manufacturers are developing rebar using recycled steel or green alternatives like basalt fiber and GFRP to reduce environmental impact.

Reinforced steel enhances the tensile strength of concrete structures, making them more durable and resistant to cracking and collapse under tension.

When properly installed and protected, reinforced steel can last 50–100 years or more. Using corrosion-resistant coatings or materials can extend its lifespan.

Yes. Most reinforced steel is 100% recyclable, and recycling rates in the construction industry are among the highest globally.

Rebar is a specific form of reinforced steel—typically in bar or mesh form—that is used inside concrete. "Reinforced steel" is the broader term encompassing all steel used for concrete reinforcement.

Yes, but the type must match the environment. For coastal areas, epoxy-coated or stainless steel is recommended to prevent corrosion.

Reinforced steel remains an irreplaceable component of the global construction industry. With its unmatched ability to support tensile loads and improve the lifespan of concrete structures, it's a material that no serious builder can ignore. By selecting the right type and ensuring proper installation, reinforced steel can offer decades of reliable service—even in the most demanding conditions.