Views: 0 Author: Rachel Wynn Publish Time: 2025-05-30 Origin: Site

Building wire is the backbone of any residential, commercial, or industrial electrical system. Choosing the right type of wire is critical to ensuring electrical safety, compliance with standards, and optimal energy efficiency. In this comprehensive guide, we will explore everything you need to know about building wire — from its types and applications to installation tips, safety standards, and frequently asked questions.

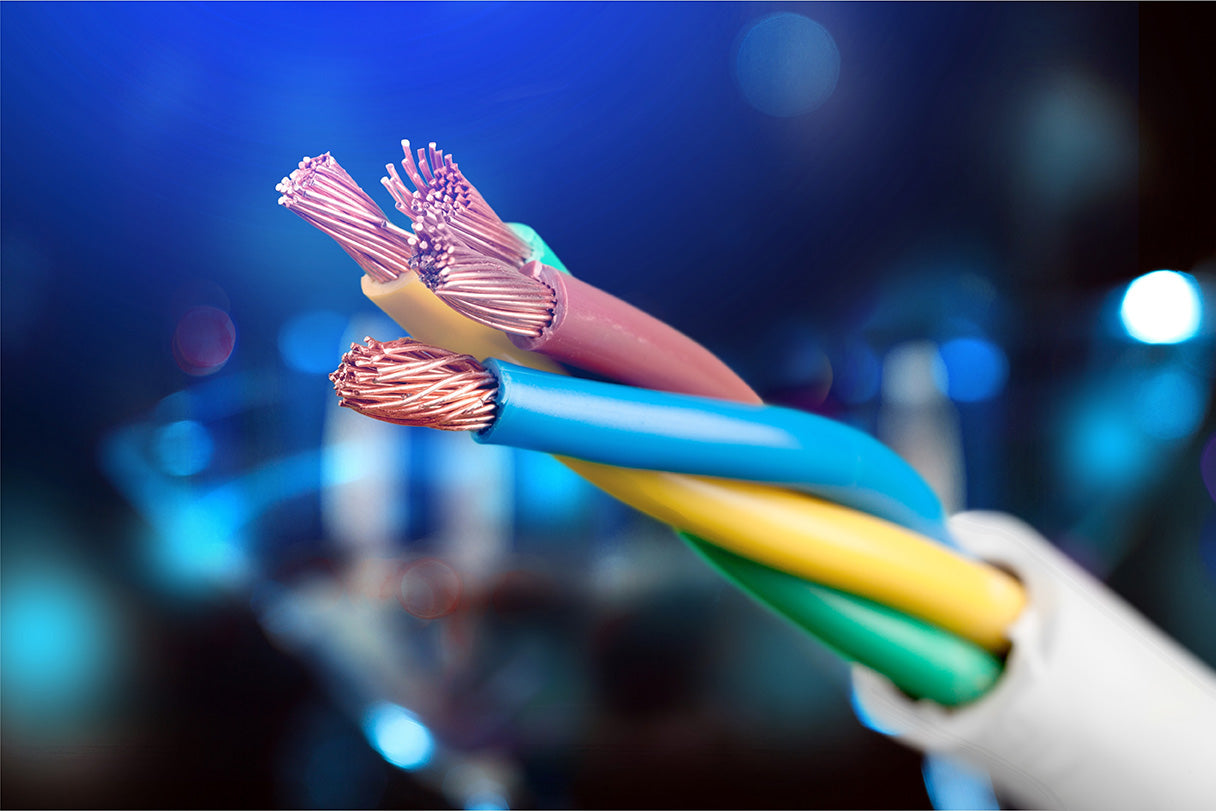

Building wire refers to electrical conductors used to distribute power within buildings and structures. These wires are designed to carry electrical current to outlets, switches, and appliances. They come in various materials, insulation types, and configurations, each tailored to specific environmental and load conditions.

Different building projects require different types of wire. Here's a detailed comparison of the most widely used building wires:

| Wire Type | Description | Common Applications |

|---|---|---|

| NM-B (Non-Metallic) | Also known as Romex. Includes multiple conductors and a ground wire inside a PVC sheath. Only for dry indoor use. | Residential interior circuits, lighting, receptacles |

| THHN (Thermoplastic High Heat-Resistant Nylon-coated) | Single conductor with heat and moisture resistance. Requires conduit protection. | Commercial and industrial conduit wiring |

| UF (Underground Feeder) | Solid, moisture-resistant wire designed for underground and wet locations. | Outdoor lighting, landscape wiring, direct burial |

| MC (Metal-Clad) | Armored cable with multiple insulated conductors inside a metal jacket. Offers physical protection. | Industrial wiring, commercial facilities, exposed areas |

| AC (Armored Cable) | Similar to MC but with a bonding strip instead of a ground conductor. Provides good mechanical protection. | Hospitals, office buildings, drywall construction |

Making the right choice in building wire isn't just about availability — it's about matching technical specifications to application requirements. Here are the essential factors to consider:

Wire Gauge (AWG): The wire thickness affects its current-carrying capacity. Lower numbers mean thicker wires, capable of handling more current.

Voltage Rating: Ensure the wire can safely handle the system's voltage. Common ratings include 300V, 600V, and 1000V for heavy-duty industrial use.

Insulation Type: Different environments demand specific insulation — for example, THHN for heat, UF for moisture, or XLPE for chemical resistance.

Temperature Rating: Building wires should be rated to withstand expected ambient temperatures, typically ranging from 60°C to 105°C or higher.

Code Compliance: Always check that your wire is compliant withNECand is UL listed or certified by equivalent bodies.

The conductor material plays a crucial role in both performance and price. The two primary options are copper and aluminum:

| Material | Advantages | Disadvantages |

|---|---|---|

| Copper | High conductivity, durable, corrosion-resistant, lower resistance | More expensive, heavier |

| Aluminum | Cost-effective, lightweight, easier to install in large sizes | Less conductive, prone to oxidation, needs larger gauge |

Use the correct conduit type for THHN or MC wire to meet code and protect from damage.

Avoid sharp bends or crushing during installation to maintain insulation integrity.

Label wires clearly in distribution panels and junction boxes for future maintenance.

Use anti-oxidant compound when connecting aluminum wires to prevent corrosion.

Always turn off power before installation and use appropriate personal protective equipment (PPE).

NM-B (Romex) is the most common and safe wire used in residential settings when installed correctly. It is designed for dry, indoor use and comes with grounding to ensure safety.

Not by itself. THHN must be installed inside a weatherproof conduit if used outdoors. For direct burial or wet environments, use UF wire or specialized outdoor-rated cable.

Determine the total load in amperes, the distance of the run, and whether the environment is hot or involves voltage drop risks. Then refer to an AWG ampacity chart or consult with a licensed electrician.

Typically: Black/red for hot, white for neutral, green or bare for ground. However, colors can vary by country and application — always confirm with your local electrical code.

Yes, but it requires special connectors rated for both metals and the use of an anti-oxidant compound to prevent corrosion and potential failure at the junction.

Building wire is more than just a piece of copper or aluminum with insulation — it’s the silent foundation that keeps power flowing reliably and safely throughout a building. Understanding the types, characteristics, and installation practices of building wire is key to avoiding hazards and maximizing performance. Whether you're planning a new construction project, upgrading your electrical system, or ensuring code compliance, selecting the right wire will save time, cost, and prevent future issues.