Views: 0 Author: Rachel Wynn Publish Time: 2025-05-28 Origin: Site

The sheet metal roller, also referred to as a slip roll or plate rolling machine, is a cornerstone tool in metal fabrication. With industrial demand surging for precise forming and cylindrical shaping, selecting the right roller is crucial for workshop productivity and output quality. This comprehensive 2025 guide dives deep into types, applications, configurations, selection strategies, and maintenance tips for professionals in fabrication, automotive, aerospace, and beyond.

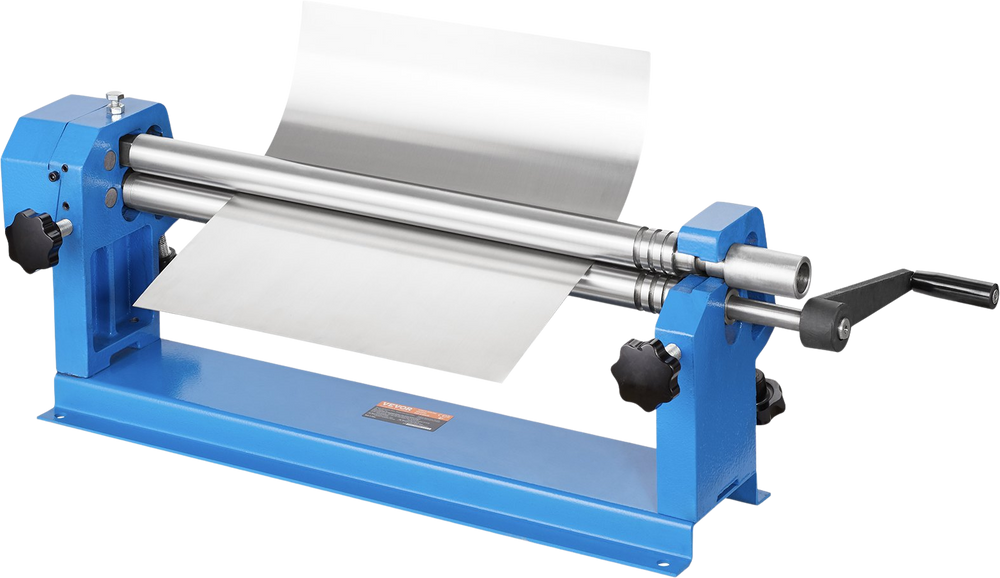

A sheet metal roller is a mechanical machine used to form flat sheet metal into curved shapes, typically cylindrical or conical. It uses a trio or more of rollers positioned to apply pressure and guide the material through, gradually bending it into a desired arc.

Different sheet rolling machines serve varied industrial needs. Below is a classification based on roller configuration and operation mode:

| Type | Description | Use Case |

|---|---|---|

| Manual Slip Roll | Hand-operated roller, usually three-roll, suited for light-gauge metals. | DIYers, art metalwork, small shops |

| Motorized/Electric Roller | Powered by electric motors, with foot pedal or switch control for consistency. | Mid-sized workshops, HVAC production |

| Hydraulic Roller | Heavy-duty machines using hydraulic power for high-thickness plates. | Shipbuilding, structural steel, pressure vessels |

| CNC 4-Roll Plate Roller | Computer-controlled system for automated pre-bending and rolling operations. | High-volume production, aerospace, energy sector |

Material Thickness Capacity: Indicates the maximum gauge the machine can roll, usually expressed in mm or inches.

Working Width: The width of the sheet metal the roller can accommodate, typically from 500mm to over 3000mm.

Minimum Rolling Diameter: The smallest diameter tube or cylinder that can be formed.

Roll Material: Hardened steel or alloyed rollers enhance lifespan and reduce surface marking.

Control System: Manual, semi-auto, or full CNC—determines precision and repeatability.

| Technology | Benefit | Example Use |

|---|---|---|

| CNC Integration | Enables precise programming and repeatable automated runs | Mass production of pressure tanks |

| Hydraulic Synchronization | Maintains roller alignment under load | Ship hull fabrication |

| Laser-guided Adjustment | Visual assistance for edge alignment | Architectural metal forming |

| Smart HMI Panels | User-friendly interfaces for diagnostics and data logging | Industrial automation environments |

Automotive: Exhaust systems, cylindrical chassis parts

HVAC: Round ductwork and sheet transitions

Oil & Gas: Pressure vessel fabrication

Construction: Metal roofing, structural beams

Aerospace: Precision cylindrical forming of lightweight alloys

Define the thickest and widest material you will process regularly.

Consider your production volume—manual for low volume, CNC for industrial use.

Choose 4-roll over 3-roll systems for easier pre-bending and automation.

Review after-sales support, parts availability, and software compatibility.

Balance budget with long-term ROI—CNC machines offer scalability.

Lubricate all bearings and gears monthly.

Clean rollers after each job to prevent surface rust or scoring.

Calibrate digital controls and pressure systems quarterly.

Train operators on emergency stop and overload prevention protocols.

Use material-specific rolling techniques to avoid microcracks or uneven bends.

3-roll machines often require manual pre-bending of the material's leading edge. 4-roll machines automate this process, improving precision and efficiency—ideal for production environments.

Yes, but roller hardness and finish should suit the material to prevent galling. Use separate rollers or cleaning procedures when switching metals to avoid contamination.

The minimum diameter depends on the material yield strength and roller configuration. As a rule of thumb, it should be about 1.5–2 times the upper roller diameter for mild steel.

For high-precision, repeatable, and large-volume production, CNC rollers reduce setup time, improve accuracy, and allow for integration into digital workflows—making them cost-effective over time.

With proper maintenance, industrial-grade rollers can last 10–20 years. Key components such as gears, motors, and bearings may require replacement after several thousand operating hours.

The sheet metal roller is more than just a bending tool—it’s a precision engineering asset for modern fabrication. Whether you’re upgrading from a manual model or investing in CNC automation, understanding specifications, applications, and technology trends can empower your decision-making. In 2025, advanced rollers are leaner, smarter, and more integrated than ever—make sure your production keeps pace.