Views: 0 Author: Rachel Wynn Publish Time: 2025-05-23 Origin: Site

16 gauge steel is approximately 0.0625 inches (1.59 millimeters) thick. This measurement can vary slightly depending on the type of steel—carbon steel, galvanized steel, or stainless steel—but generally, 16 gauge offers a balanced thickness that is strong yet workable. It is widely used in construction, automotive, and manufacturing due to its moderate strength, corrosion resistance (in stainless variants), and ease of fabrication. If you're selecting steel for a project and see "16 gauge" , you can reliably expect a thickness near 1.6 mm, suitable for applications requiring durability without excessive weight.

The term "gauge" refers to the thickness of a material, and in the case of steel, it is measured using a standardized system known as the gage or gauge system. This system works in reverse: the lower the gauge number, the thicker the steel, meaning 10 gauge is thicker than 16 gauge. The gauge number is a unit of measurement that indicates how many times a piece of metal has passed through rollers to achieve a specific thickness.

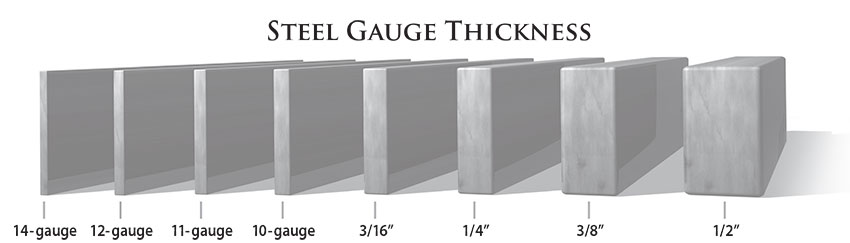

To understand how 16 gauge steel fits into the larger context of steel thickness, it is essential to compare it to other common gauge numbers. The table below shows the conversion of different steel gauges into inches and millimeters:

| Gauge | Thickness (inches) | Thickness (mm) |

|---|---|---|

| 10 | 0.1345 | 3.42 |

| 12 | 0.1045 | 2.67 |

| 14 | 0.0781 | 1.98 |

| 16 | 0.0625 | 1.59 |

| 18 | 0.0478 | 1.21 |

| 20 | 0.0359 | 0.91 |

As shown in the chart, 16 gauge steel has a thickness of 0.0625 inches or 1.59 millimeters. This thickness makes it suitable for a variety of applications, as it strikes a balance between strength and workability.

16 gauge steel is known for its versatility and is used in numerous industries where strength and durability are important. The material is often selected when a moderate level of thickness and structural integrity is required, but extreme weight or cost concerns are a factor. Let’s look at the most common uses for 16 gauge steel.

In the automotive industry, 16 gauge steel is widely used for producing parts that require both strength and flexibility. This includes components like body panels, chassis parts, and exhaust systems. The material’s durability ensures that automotive parts can withstand wear, impact, and weather conditions without becoming too heavy, which is critical for performance.

In the construction industry, 16 gauge steel is commonly used for framing, wall studs, and roofing applications. Its strength is adequate for supporting structural loads without excessive weight, making it a suitable choice for light commercial and residential construction. It is also used for making steel doors, windows, and structural reinforcements.

Many household appliances, including dishwashers, microwaves, and refrigerators, use 16 gauge steel for their outer casings or internal components. The material is strong enough to protect the internal parts while being light enough to keep the overall weight of the appliance manageable. The corrosion-resistant properties of stainless steel also ensure long-lasting performance, particularly in humid or high-moisture environments like kitchens.

For DIY enthusiasts and hobbyists, 16 gauge steel is a popular choice due to its versatility. It is used in custom fabrication projects, such as furniture, decorative panels, storage units, and even art installations. The material is easy to work with using basic tools like cutting torches, grinders, and welding equipment.

When choosing the right material for your project, 16 gauge steel offers several key advantages:

Strength: Despite being thinner than heavier gauges, 16 gauge steel is still strong enough to handle heavy-duty applications, providing a good balance between durability and weight.

Versatility: It’s widely used in automotive, construction, and manufacturing industries, and it’s equally suitable for home improvement and custom projects.

Workability: 16 gauge steel can be cut, welded, and formed using standard metalworking tools, making it easy to shape and modify for specific needs.

Corrosion Resistance: When using high-quality stainless steel variants, 16 gauge steel offers excellent resistance to rust and corrosion, particularly in environments exposed to moisture, chemicals, and temperature fluctuations.

Despite its many advantages, 16 gauge steel does have some limitations, particularly when compared to thicker steel grades:

Less Durability for Heavy-Duty Applications: For extremely heavy or load-bearing structures, thicker gauges like 14 gauge or 10 gauge might be more appropriate, as they provide greater strength and resistance to stress.

Not Suitable for Extreme Weight Reduction: In applications where weight is a critical factor, such as in aerospace or some automotive parts, 16 gauge steel may be too thick, and lighter materials like aluminum might be preferred.

16 gauge steel is strong enough for moderate-duty applications, such as automotive parts, framing, and home appliances. It is commonly used for structural components where moderate strength is required, but for extremely heavy-duty applications, thicker gauges might be more appropriate.

Yes, 16 gauge steel can be easily welded using MIG, TIG, or stick welding methods. Its thickness allows for good penetration, making it a popular choice for both professional and DIY welders.

14 gauge steel is thicker than 16 gauge steel, measuring 0.0781 inches (1.98 mm) in thickness. This makes 14 gauge steel stronger and more resistant to bending and deformation. However, 16 gauge steel is lighter and more cost-effective, making it a better choice for applications that don’t require the additional strength of 14 gauge steel.

Yes, 16 gauge steel is suitable for exterior use, particularly if it's made from stainless steel or galvanized steel. These materials provide excellent protection against rust and corrosion, making them ideal for outdoor applications like fencing, roofing, and exterior panels.

The most common types of 16 gauge steel are carbon steel and stainless steel. Stainless steel is often used in environments where corrosion resistance is critical, while carbon steel is typically used for structural and industrial applications.

16 gauge steel is a versatile and widely used material that strikes an excellent balance between strength, workability, and cost. It is commonly used in automotive, construction, and home appliance manufacturing, and it is also popular for DIY and custom fabrication projects. Understanding the thickness and properties of 16 gauge steel will help you make informed decisions when selecting materials for your next project. Whether you're working on structural reinforcements, home improvements, or industrial applications, 16 gauge steel offers the durability and flexibility needed to get the job done efficiently.