Views: 0 Author: Rachel Wynn Publish Time: 2025-06-04 Origin: Site

Hammered copper sheet metal is simply copper that has been hammered or pressed to create a textured surface. The process of hammering copper creates a variety of finishes, ranging from subtle textures to more pronounced, dramatic patterns. The result is a piece of copper sheet that not only maintains its functional properties but also gains an attractive appearance that adds depth and character to any product it is used for. Hammered copper sheet metal is incredibly versatile and can be used in various industries and applications. Below are some of the most common uses: Hammered copper is often used in architectural projects to create distinctive and eye-catching designs. Whether it’s for roofing, siding, or decorative elements like trim and fascia, the hammered texture adds a level of elegance that enhances the overall aesthetic of a building. It is particularly popular for vintage-style and rustic designs, as well as high-end residential and commercial projects. One of the most popular uses of hammered copper is in the creation of sinks and countertops. The unique, textured surface gives the sink or countertop a rustic yet sophisticated look, making it a popular choice for kitchens and bathrooms. The hammered finish also helps mask scratches and watermarks, maintaining the copper's beauty even with heavy use. Hammered copper is widely used in home décor items such as lamps, wall art, mirrors, and cabinet hardware. Its warm, metallic tone complements both modern and traditional interior designs, making it an ideal choice for homeowners looking to add a touch of luxury to their living space. Artists and artisans often use hammered copper sheet metal to create sculptures, jewelry, and other decorative pieces. The textured surface provides a beautiful interplay of light and shadow, enhancing the visual appeal of the artwork. Hammered copper is particularly popular for custom art pieces and personalized gifts, adding a unique and timeless feel. Beyond aesthetics, hammered copper also has functional uses in industrial applications. It is used in the production of components such as electrical parts, heat exchangers, and components in machinery that require excellent corrosion resistance and thermal conductivity. The durability of hammered copper makes it a valuable choice in these types of applications. There are numerous benefits to using hammered copper sheet metal in various projects, ranging from aesthetics to functionality. Here are some of the main advantages: The hammered finish of copper sheet metal provides a stunning, textured surface that adds visual interest to any project. The interplay of light and shadow on the surface makes hammered copper an eye-catching material, perfect for creating focal points in design projects. It is often used for both functional and decorative elements due to its unique and luxurious appearance. Copper is a highly durable metal that can withstand exposure to the elements. When used in exterior applications like roofing or siding, hammered copper sheet metal can last for decades, even centuries, without showing significant wear. Its natural resistance to corrosion and weathering means it doesn’t require extensive maintenance or replacement. One of the defining characteristics of copper is its ability to develop a beautiful patina over time. This greenish-blue film forms naturally as the copper reacts with the environment, especially in outdoor applications. The patina not only protects the copper from further corrosion but also gives it a unique, aged look that many people find appealing. Hammered copper develops this patina beautifully, adding to its charm. Copper is a 100% recyclable material, making it an environmentally friendly choice. Recycled copper can be used to create new hammered copper sheet metal, reducing the demand for raw copper and minimizing environmental impact. Additionally, copper’s long lifespan reduces the need for frequent replacements, further benefiting sustainability efforts. Because of its resistance to corrosion, hammered copper sheet metal requires very little maintenance. Over time, it may develop a patina, but this is a natural process that many people find desirable. To maintain its appearance, simply clean it with a soft cloth and mild soap when necessary. No additional coatings or treatments are usually required, making it a cost-effective choice for long-term use. The price of hammered copper sheet metal can vary depending on a number of factors, including the thickness of the sheet, the finish, and the supplier. On average, hammered copper sheet metal ranges from $10 to $20 per square foot. However, prices can increase for higher-quality copper, intricate patterns, or custom designs. Below is a general price breakdown: Working with hammered copper sheet metal requires certain tools and techniques to ensure that the metal is cut, shaped, and installed correctly. Here are some tips for working with hammered copper: Use the Right Tools: When cutting hammered copper, use sharp shears or a metal cutter to avoid damaging the metal. For larger projects, a saw with a fine-toothed blade may be needed. Wear Protective Gear: Copper can have sharp edges when cut, so always wear gloves and safety glasses to protect yourself. Consider Professional Help: For larger or more intricate projects, it may be wise to consult a professional metalworker or artisan who specializes in copper to ensure high-quality results. Keep the Finish Clean: Regular cleaning and maintenance will help preserve the hammered texture and natural patina, ensuring the longevity of your copper project. A: Hammered copper sheet metal is copper that has been physically hammered to create a textured surface. This process adds visual interest and durability, making it an ideal material for a variety of applications. A: Hammered copper is durable, resistant to corrosion, and develops a beautiful patina over time. It also has aesthetic appeal and is environmentally friendly due to its recyclability. A: The price of hammered copper sheet metal typically ranges from $10 to $20 per square foot, depending on factors such as thickness, quality, and customization. A: Hammered copper requires very little maintenance. It may develop a natural patina over time, which many people find desirable. Regular cleaning with a soft cloth and mild soap is usually sufficient to maintain its appearance. A: Yes, hammered copper is often used for roofing due to its durability and resistance to corrosion. It is a popular choice for both residential and commercial buildings, providing a long-lasting, attractive finish.

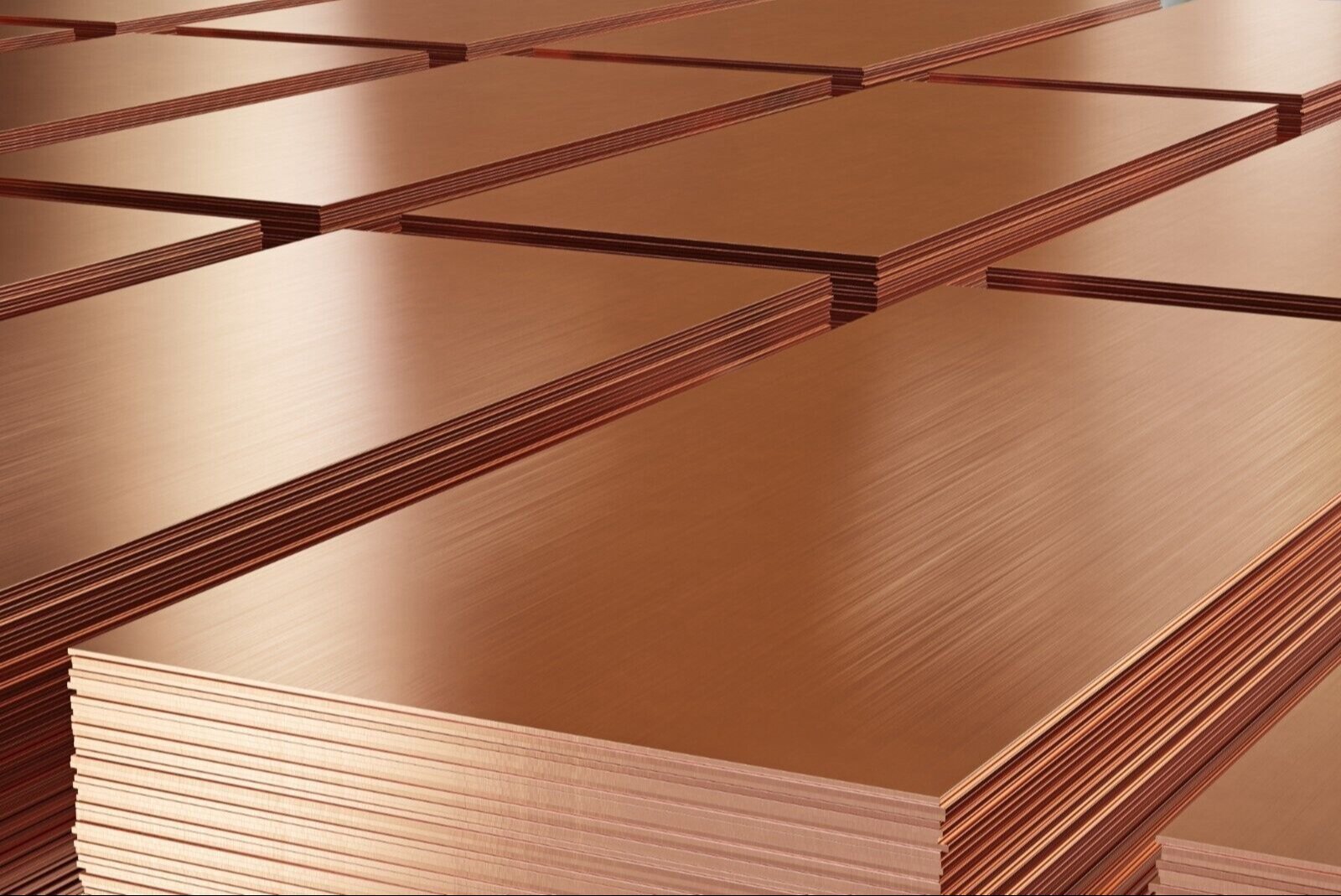

What is Hammered Copper Sheet Metal?

Applications of Hammered Copper Sheet Metal

1. Architectural Design and Construction

2. Copper Sinks and Countertops

3. Home Decor

4. Artistic and Decorative Items

5. Industrial Applications

Benefits of Using Hammered Copper Sheet Metal

1. Aesthetic Appeal

2. Durability and Longevity

3. Natural Patina

4. Environmental Benefits

5. Low Maintenance

Pricing for Hammered Copper Sheet Metal

How to Work with Hammered Copper Sheet Metal Type of Hammered Copper Price per Square Foot (USD) Standard Hammered Copper $10 - $12 High-Quality Hammered Copper (Thicker Sheets) $15 - $20 Custom Hammered Copper Designs $20+

FAQ

What is hammered copper sheet metal?

What are the benefits of using hammered copper?

What is the price of hammered copper sheet metal?

How do I maintain hammered copper?

Can hammered copper be used for roofing?